It’s no surprise warehouse processes have grown more complex in the on-demand economy. Greater demand and higher customer expectations mean employees must move product through the warehouse as efficiently as possible.

Warehousing technology has evolved to meet these challenges, helping employees better track inventory through the receiving and put-away processes. While these advancements address concerns within individual warehouses, they don’t provide a solution for tracking inventory throughout the supply chain. Manufacturers needed a standard system to guarantee they’d have complete visibility into shipments as they arrived.

That’s why manufacturers in industries such as food and beverage turned to GS1 standards. GS1 is a not-for-profit organization that maintains standards for business communication.

GS1’s leadership in barcode innovation stretches back more than 40 years, but we’ve yet to achieve universal adoption of GS1 standards. Even some warehouses that work with GS1 standards maintain redundant barcoding processes.

Greater adoption of GS1 standards could transform the way we work with barcodes and help warehouse managers achieve maximum efficiency.

Barcodes: A step forward—but how extensive?

It wasn’t long ago that most warehouses relied on manual inventory processes. Trucks would arrive, workers would take stock using pencils and paper, and items would be placed on the shelf. For managers, however, these processes were headache-inducing: If one employee recorded a wrong number while receiving stock, the consequences would ripple across the warehouse.

RF scanners erased much of the manual burden—staff could scan a barcode rather than relying on a physical record. By adding an extra set of “eyes” to the receiving and putaway processes, warehouse operators were able to achieve higher levels of inventory validity.

Still, because these barcodes contained little information beyond item listing, it was entirely possible employees could miss inventory or count it incorrectly. Supply chain innovators have introduced various solutions for the issue; for instance, advanced shipping notices provide recipients with critical inventory information, giving their team greater visibility into what stock, and how much, should arrive.

However, GS1 standards deliver the same information—and because some of the world’s largest industries follow these guidelines, greater GS1 standard adoption is a natural solution.

GS1 labels: A standard for excellence

Companies that utilize GS1 labels comply with standards for what information is kept on barcodes—such as the weight of each case, or the quantity of cases. When you scan a GS1 barcode, you’ll know which, what kind, and how many of each product is located on the pallet. GS1 also provides standards for every step in the shipping process, including label placement and barcode color.

The challenge isn’t convincing warehouse operators to ship using GS1 labels—in fact, many warehouses receive shipments with GS1 tags on inventory, and many must place GS1 tags on items before they’re shipped.

Errors are likely to occur when warehouses place their own label on an item while it’s in inventory. This process not only wastes paper, but it also risks data loss or duplication. Because GS1 tags come with a unique identifier for the product and a unique serial number for each case that will never be duplicated, there’s no need for an internal barcoding system.

By adhering to GS1 standards, warehouses also improve traceability—a hot topic among supply chain innovators. Take, for instance, food manufacturers. Technology allows food and beverage suppliers to track every location a raw material has been during production. If there were to be an outbreak of food-related illness in a concentrated area, GS1 standards would provide manufacturers a common language to research and determine the contaminant.

Technology for a better supply chain

Today’s supply chain demands efficiency. As warehouses do more with less, demand rises for solutions that streamline operations. If you receive GS1-labeled inventory but maintain an internal barcoding system, it’s time to consider dropping the redundant process. If you don’t currently work with GS1 barcodes, consider moving to a system that helps improve inventory validity and traceability across your supply chain.

The layman might envision warehousing storage services as simply a very large storage unit where pallets of bulk shipments simply sit and wait.

Yourkey Warehousing professionals recognize that there’s much more to safe and efficient warehousing than a lot of building space. Savvy businesses find warehousing in highly accessibly areas, like Hong Kong, Shenzhen, Guangzhou, Shanghai, Ningbo and Xiamen so that goods are within quick reach of end users. But location access isn’t the only critical component of smart warehousing. Technology is key. Yourkey Warehousing has implemented a secure, state-of-the-art, web-based Inventory Management System, allowing you to view your inventories anytime and from anywhere. EDI and barcoding capabilities are included, which enables you to organize your resources and optimize your fulfillment and distribution processes. Keep track of everything from start to finish with this exceptional system.

There are more about our warehousing services as below.

Yourkey Warehousing Logistics

Contract, Public and Food Grade Warehousing

Full-Service Fulfillment

Container Unloading and Cross Docking

Pick and Pack, Repack, Sort and Segregate

Kitting and Assembly Services

Local and International Logistics

Distribution

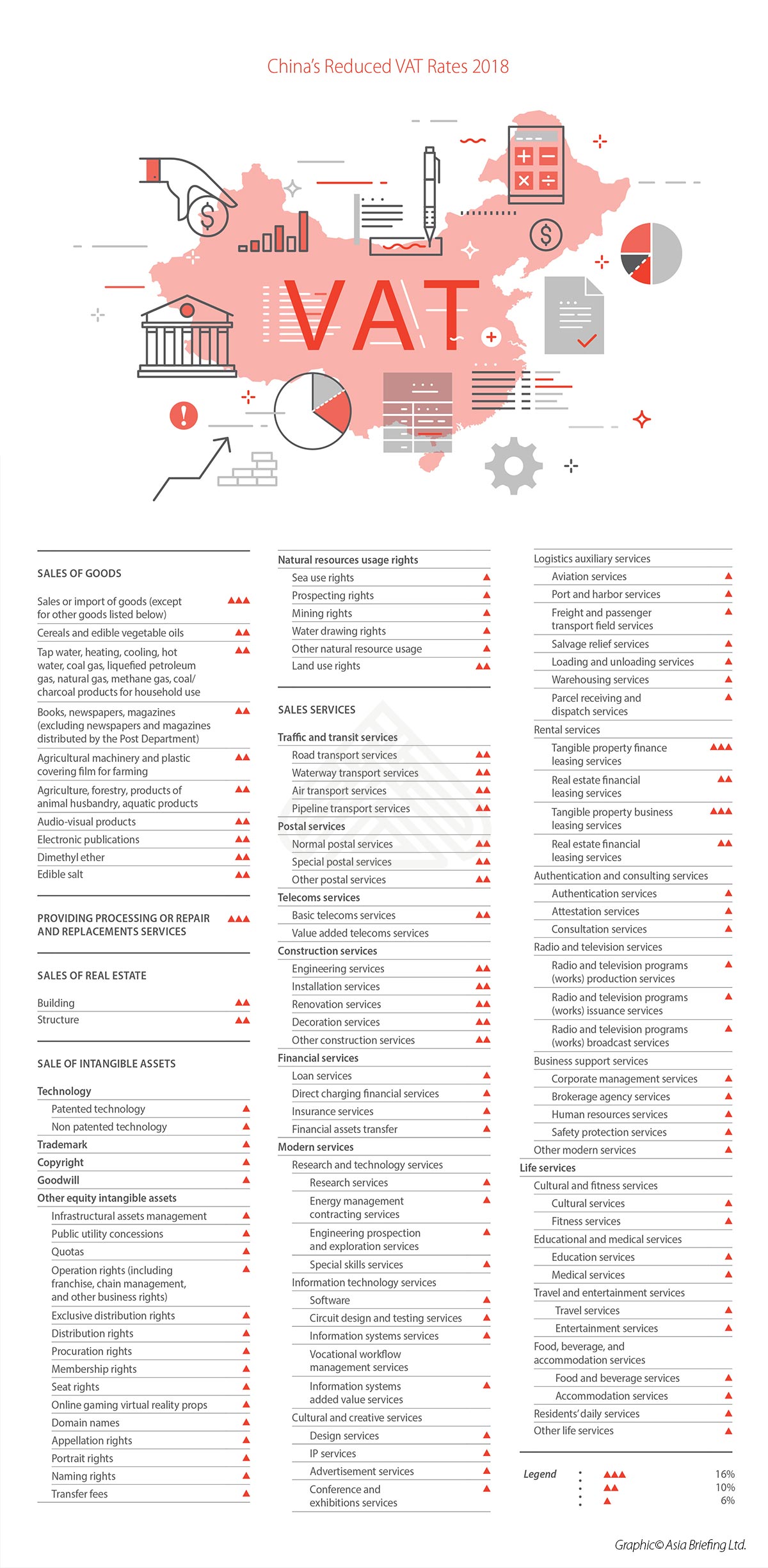

China recently lowered its value-added tax (VAT) rates, as part of an RMB 400 billion (US$64 billion) tax cut package.

The Ministry of Finance (MOF) and the State Administration of Taxation (SAT) recently released the Circular about Adjusting the Rates on Value-added Tax, which explain the details of the new VAT rates.

According to the circular, the tax cuts reduce the 17 percent VAT bracket to 16 percent, and the 11 percent VAT bracket to 10 percent. The six percent VAT bracket remains unchanged. The new VAT rates will go into effect on May 1, 2018.

The MOF and SAT also recently released the Circular about Unifying the Standards of Small VAT Taxpayers, which expands the criteria for firms to qualify as a small-scale VAT taxpayer. Small-scale VAT taxpayers are now defined as those whose annual sales are less than RMB 5 million (US$796,330). Before, there were three different tiers of small-scale VAT taxpayers.

The tax cuts are part of an ongoing effort to optimize the VAT system and reduce companies’ tax burdens. At the annual Two Sessions meetings in March, Premier Li Keqiang stated that the government aims to further streamline the VAT system by reducing the number of VAT brackets from three to two.

China’s updated VAT rates follow.

Having right things at the right place and right time is important and Internet of Things (IoT) plays a big role in ensuring the whole process runs smoothly. When we generally talk about IoT, it is generally tagged to electronics, wearables or making lifestyle more personalized and smarter. But there is much more to this technology. One sector where IoT has made a major impact is logistics. Technology has been a major differentiator in the logistics and supply chain. Whether it is warehouse management, fleet management, delivery or shipment, IoT has majorly made its impact. So let’s understand how IoT enables logistics and supply chain management.

IoT has a deep penetration

Whether maintaining quality of consignments, tracking your employee from a centralized place, managing workforce or monitoring your energy bills and wastage, IoT can manage it all for you. Agreeing to this fact, Ali Hosseini, Founder and CEO, SenRa Tech, in 26thConvergence India 2018 conference in New Delhi, India said, “So, where is the cargo? Where are the drivers going? Has the cargo been opened, monitoring cargo quality, temperature, etc. For all this IoT is must. Asset tracking is really big. We collaborate with providers who have tracking sensors and the data collected is sent to the Cloud and is then analyzed to the optimum level.”

While the technology caters to the B2B solutions, it also delves into B2C solutions too. The technologies used in smart cities are now being used by companies to create innovative solutions.

However, in order to make the technology reach a wider population, the academia need to train industry-ready professionals who can make solutions that can cater to the needs of the customers and businesses.

ALSO READ: Digital Convergence – The future of breathtaking socio-economic developments

Academia training workforce

According to the World Bank, Indian logistics industry has jumped from 35% to 54% in recent times. Right from tracking consignments to monitoring theft in real-time, IoT can be a big help to ensure smooth working. However, to take this technology to a larger audience, the academia needs to play a major role. Jatin Talreja, CMD, Riyanix says, IoT is going to be everywhere. The privacy will be breached in future. However, there is no choice. It is not only going to help businesses but also increase efficiency of employees The academia has to restructure its courses to train workforce that are industry-ready and understand the technology well.”

Satellite-based IoT

Another area where there is a huge scope is building satellite power with IoT. Space-based IoT can reach to rural areas. It is cost-effective and reliable. Agriculture is another sector which will benefit hugely. It can help in increasing farm production and stop wastage, etc.

Elaborating on this Scott Larsen, CEO, Helios Wire, says, “Our goal is to democratize IoT and make it available to everyone. Our business model is to build 30 satellites that will give a boost to this technology. They are relatively inexpensive.”

Customizing it for India

If we take an example of e-commerce logistics, you can see how businesses are customizing their products to tap the fast opportunity in India. Delhivery is one such company that has customized to leverage the technology and use it effectively to reach large population.

What it does is that through a simple smartphone it collects data, through data science technology it collates and breaks the location based on pins. In the process the company gets to know the traffic pattern of the location. How much time, money and resources will be needed to cover a location area, so that it can deliver the packages at the exact location and the time mentioned to the customer.

Srinivasan S, Senior Director, Data Science, Delhivery says, “We get to know how difficult the locality is. It increases our efficiency and helps us to maintain better customer relationship. We also get to know the whereabouts of our employees in real-time.”

How does a Warehouse Management System ( WMS ) fit into your supply chain?

In a fully integrated solution you will have your raw materials received into your Warehouse Management System, be consumed by your Material Requirement Planning system and the finished goods be deposited back into the WMS. The WMS will facilitate the tracking of the product through moves and cycle counts while in the warehouse, then finally be picked and sent to either the shipping system or Transportation Management System to route your trucks. The entire time your Enterprise Resource Planning system will be tracking the values, orders, sales, and invoices with all of the systems.

What to look for in a Warehouse Management System ( WMS )

There are different types of WMS ranging from simple uncomplicated systems to more complex ones that are more suited for large warehouses. When looking for a WMS system for your warehouse, there are different factors you need to consider before you can settle on one WMS. Some of the things to consider include

Functions

Different WMS can perform different functions and are built for different industries. What functions does your business need to meet to satisfy the needs of your customers, any regulating bodies, and your shareholders? Look for a warehouse management system that is configurable and able to scale past where you are, but to where you plan to be in five years.

Warehouse size

Larger warehouses require more detailed systems than smaller ones. This is because more activities and functions are carried out in a large warehouse and all such activities and functions require a more detailed system. The larger the warehouse, the higher the cost of travel between locations, and therefore the more important detailed tracking is.

Customer needs

By identifying the loopholes in your current system, you will be in a position to determine the functions you require in a WMS, and select a WMS that will ensure that you are able to serve your customers better and increase their satisfaction with the services you provide. Are you an ecommerce site that needs auto-allocation so your available inventory is always accurate? Do you need to post tracking numbers to your customers? Do you need lot tracking to comply with FDA regulation?

Cost

The cost of installing a WMS system differs greatly depending on the complexity of the system and the system vendor. Choose a WMS system that will serve your warehouse better by fulfilling all the required functions, and also one that your business can afford. Choosing a system that is way too expensive for you will only put your business in trouble and end up compromising the quality and efficiency you so much want to improve. Choosing a basic WMS system on the other hand might not serve you sufficiently, especially, if you have many functions in your warehouse. You have to find the right balance between cost and functions when choosing the right WMS for your business. Don’t get caught thinking what your business needs are today, think of where your business needs to be in 5 years and choose a product that can take you there and beyond.

What is a WMS?

A Warehouse Management System, or WMS, is used to record and manage almost all activity inside a physical warehouse of goods. This includes everything from shipping, to receiving, putaway, picking, packing, and more. If the warehouse is public, the system can also monitor the ownership of each item by customer.

Sophisticated WMS systems are also designed to integrate with a wide range of internal and external software systems, including Enterprise Resource Planning Systems, Supply Chain Management Systems, Inventory Management Systems, Transportation Management Systems, Barcode Scanning Systems, and eCommerce platforms.

Such systems can also communicate with other customers, vendors, and suppliers through technologies like Electronic Data Interchange (EDI) and UCC-128 Label Printing.

Who Uses Warehouse Management Systems?

Warehouse Management Systems are used by a wide range of operations charged with managing, shipping, and monitoring physical inventory. This can include both public warehouses, known as Third Party Logistics companies (3PLs), as well as private warehouses.

Private warehouses are operated by businesses in almost every major industry, including healthcare, automotive, cold storage, medical supply, aeronautics, telecommunications, consumer goods, electronics, computers, and more.

Why Use 3PL Central?

3PL Central’s WMS solutions, 3PL Warehouse Manager and yourkey logistics, provide easy-to-use, on-demand warehouse management software for 3PLs, public warehouses and warehouse operations of all kinds, helping them run more efficiently, grow their business and satisfy all of their customers, partners, and vendors.

3PL Central is a leader among on-demand supply chain software providers, offering warehouse management solutions that are robust, reliable, secure, cost-effective and easy to use. A proven success in the challenging 3PL warehouse environment, 3PL Warehouse Manager was the first on-demand Warehouse Management System (WMS) built specifically for 3PLs. Its sister product, Red Rock Warehouse Manager WMS, benefits from robust functionality, affordability and the years of experience 3PL Central has in the cloud environment serving the warehousing and logistics industry. The products have grown exponentially, providing enterprise-class WMS functionality to a range of warehouse operations who are looking to employ a nimble SaaS WMS solution.

Companies That Use Our Products

Our customers include everyone from small-to-medium sized 3PLs to private Fortune 500 distribution centers. 3PL Warehouse Manager and yourkey logistics are offered via an on-demand, or Software-as-a-Service (SaaS) model, enabling 3PLs, public warehouses and warehouse operations of all kinds to access a world-class WMS solution for a low monthly fee.

Our software has enabled our clients to significantly reduce the total cost of ownership of supply chain execution software while freeing them from the traditional “buy, upgrade and maintain” software cycle.

What is meant by ippc in a wooden pallet?

Now almost all Customs will check the pallets of shipping products when importing to their countries. They must find the IPPC mark on the pallet, or trouble happens. What is meant by ippc in a wooden pallet?

It applies only to wood packaging materials (both coniferous and non-coniferous) made with solid wood not engineered wood products (plywood, OSB, etc.) or corrugated when used in international trade. The international standard does not apply to wood packaging material manufactured solely for domestic use.

What is IPPC?

IPPC is short for International Plant Protection Convention. They developed a standard for wood packaging in international business, called ISPM-15.

What treatment methods will be acceptable by ISPM-15?

The IPPC standard(ISPM-15) allows for two treatment methods – heat treatment and fumigation with methyl bromide. Heat treatment will likely become the most popular method due to environmental concerns caused by methyl bromide used to fumigate packaging. The standard calls for heat-treated material to be heated to 56 degrees Celsius for 30 minutes. This can be achieved by using a dry kiln or any other approved heat treatment chamber/device.

What is covered by this global standard?

softwood or hardwood packaging material such as pallets, totes, boxes, wedges, braces, dunnage, non-processed wooden articles and the like. Such items made out of manufactured wood (i.e. plywood, chip board, paper board that have been created using glue, heat and pressure or a combination thereof) are not included.

What is the components of a full mark?

ISPM 15 has guidance on 4 specific components to the labeling of wooden packaging.

IPPC Mark

The guidance on the symbol is that it must be registered under national, regional or international procedures. It must also resemble the provided symbol below.

Country Code (US)

The country code must be the two-digit International Organization for Standards (ISO) format, e.g., US for the United States, AU for Australia, RO for Romania and CN for China. It must also be separate from the producer/treatment provider code by using a hyphen.

Producer/treatment provider code

The treatment code is unique and is provided by the NPPO and given to the producer of the wood packaging material or treatment provider that will place the marks on the wood packaging material.

Treatment Code

The treatment code is an abbreviation for either heat treatment (HT) or methyl bromide (MB). The image above shows a treatment code of ‘HT’ and where it should be placed.

Do I have to concern when I import from China?

You’d better to check with your supplier in China. They must provide pallets or any wood packaging materials with IPPC marked.

And you should understand the related policy of Customs of your country, for better preparing all documents. Like Australia and New Zealand, the clearing process will need Quarantine Declaration.

IPPC marked in pallet

All our wooden pallets for packaging woven polypropylene bags are complied with IPPC regulation.

Do I have alternative options than wooded pallet?

plastic palletBesides wooden pallet, you have plastic pallet at disposal.

Plastic pallets also offer an excellent solution to pallet logistics. It lasts for a long time, and of course it costs more.

In ocean freight, the shipper issues the Bill of Lading (BL) or shipping document (express or telex release) when performing an international import or export shipment. The Bill of Lading confirms that the goods sent by the exporter to an importer have been shipped with the designated shipper. When performing this import or export, the BL may be a physical document called the ORIGINAL paper or can be done virtually. Which of these documents is necessary at different points of the shipment depends on the type of relationship you have with your ISP and country-specific regulations to which documents are delivered. Telex Release and Bill of Lading

The Bill of Ladings must be sent from the exporter to the importer either as the ORIGINAL or TELEX RELEASE. This usually depends upon whether or not the provider trusts the client and whether or not the payment has been secured. If you have confidence in the provider and the country allows it, you can do the EXPRESS OR TELEX RELEASE. This will help you save the cost of the shipping by international courier documentation.

The difference is that if you choose to use the original, the importer will have to have the original in hand to receive the goods. That said, there will be a cost to shipping the international documentation. If you opt for the TELEX RELEASE, the copy provided to the importer will be enough.

The Telex Release, as well as the Bill of Lading, are mandatory documents needed to ship internationally. Check our best rates now and see how you can send your shipment easily and at the best price.